Powering our future with sulfur

Before you leave your home, what do you take with you? Your wallet, probably your phone, maybe your laptop. Portable electronics you rely on were made possible with the invention of lithium-ion batteries.

However, advances in the storage capacity of lithium batteries has slowly stopped improving. As the world embraces electronic vehicles and moves further away from fossil fuels, we will need better technologies for storing energy.

Of all the places to find inspiration for new battery chemistry, soil might be the last place you would think to look. Yet sulfur* – an important nutrient that keeps plants healthy – may hold the key to a more sustainable battery.

Sulfur in agriculture

Without the sulfur in soil, crops produce less yield and hold less nutrition. Sulfur is a cheap and readily available nutrient, but the one big problem farmers face is that plants can only absorb sulfur after it has been converted to sulfate – sulfur bonded to oxygen atoms – which is easily washed out of soil.

Chemist Dr Chris Guppy from the University of New England spoke at the Australian Academy of Science about how farmers work around this problem.

Elemental sulfur must first be slowly converted to sulfates by microbes in the soil. Elemental sulfur poorly dissolves in water and as we know only leaches out of soil after it is converted to sulfate. Scientists have found that by combining elemental sulfur and sulfate, they can reduce how much leaves the soil.

“Elemental sulfur is the perfect input – it’s cheap and the most efficient fertiliser you can possibly add, but you do need microorganisms to oxidise it and break it down,” Dr Guppy said.

“Elemental sulfur is the perfect input – it’s cheap and the most efficient fertiliser you can possibly add."

Another way of keeping sulfur in the soil is to add glucose to the soil, and it was this agricultural phenomenon that helped Dr Mahdokht Shaibani and her team at RMIT University successfully prototype their lithium-sulfur battery.

Sulfur in batteries

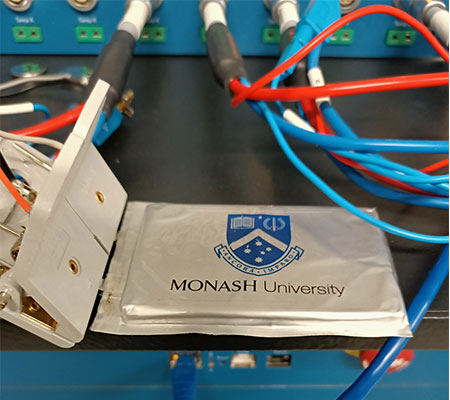

Dr Shaibani’s lithium-sulfur battery has a much greater storage capacity compared to traditional lithium-ion batteries. However, the chemistry that allows it to hold so much energy also causes the battery to physically break apart due to the stress.

Glucose helps stabilise the lithium-sulfur battery technology in a similar way it helps to keep sulfur in the soil. By adding glucose, Dr Mahdokht Shaibani’s team has created a more sustainable, lighter and longer-lasting battery that has applications for electrically powered vehicles.

“The new batteries aren’t going to replace lithium-ion batteries, they are just there to lessen the burden of rare earth metals that are used in lithium-ion batteries and unlock new applications,” Dr Mahdokht Shaibani said at the Academy event.

Prototype lithium-sulfur battery. While the commercial product is still years away, the technology works. Photo provided by Dr Mahdokht Shaibani

Lithium-ion batteries require rare earth minerals like nickel and cobalt. However minerals supply is limited, prices are rising and their mining often has a great social and environmental cost. Sulfur, by contrast, is common and relatively cheap.

The technology has a way to go yet. It faces development challenges of cost, stability and scalability, with lithium-sulfur batteries yet to reach sustainable and cost-effective production.

While lithium-sulfur batteries may not be ready today, it's highly likely that with the research underway, sulfur will be part of a more sustainable future.

*In technical and scientific writing sulfur is now standard throughout the world, although the sulphur spelling is still dominant in general use in Australian English.